Services

1) EQUIPMENT REBUILDING SERVICES

Restore. Reinforce. Reimagine.

Our equipment rebuilding process sets the industry standard for precision and reliability. Whether you're working with oilseed extraction, rendering, or feed processing machinery, we deliver a comprehensive overhaul that brings your equipment back to peak performance.

What We Do:

- Thorough Cleaning & Prep Every unit is steam cleaned and sandblasted to bare metal for a fresh start.

- Complete Disassembly & Inspection We break down each machine to inspect for cracks, welds, and structural integrity. Compromised bases are discarded to ensure safety and longevity.

- Precision Rebuilding Castings are measured for tolerance and rebuilt or replaced with new OEM parts. Gears and bearings with less than 70% life are replaced to maximize uptime.

- Seal & Motor Restoration: All seals and gaskets are replaced. Main motors are rewound or swapped out as needed for optimal performance.

- Guard Fabrication Guards are either rebuilt or custom-fabricated to meet modern standards.

- Finishing Touches Once reassembled, each machine is primed, painted, and rigorously tested before shipment.

2) START-UP ASSISTANCE & OPERATOR TRAINING

Get Up and Running with Confidence

We don’t just deliver equipment — we ensure it performs at its best from day one. Our start-up assistance and personnel training services are designed to help your team hit the ground running with maximum efficiency and minimal downtime.

What’s Included:

- Onsite Technical Supervision Our experienced technicians oversee the installation of all equipment and systems we provide, ensuring everything is set up correctly and safely.

- Start-Up Support We guide your team through the initial launch, helping you calibrate, test, and fine-tune operations for optimal performance.

- Hands-On Operator Training We train your in-house personnel on proper operation, maintenance, and safety procedures — empowering your team to run equipment with confidence and care.

- Efficiency from Day One Our goal is to help you reach full capacity quickly while avoiding costly errors or delays.

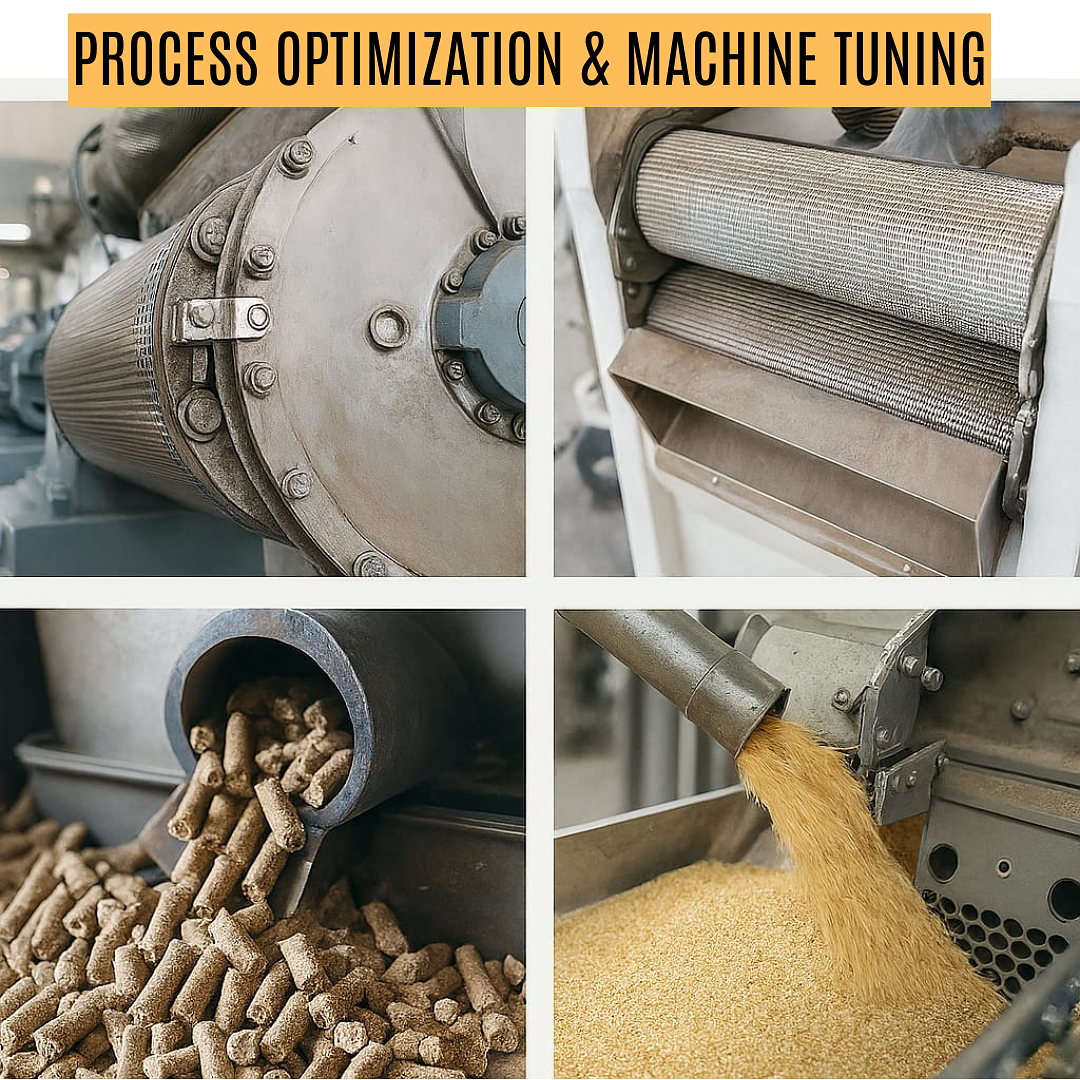

3) PROCESS OPTIMIZATION & MACHINE TUNING

Maximize Output. Minimize Waste.

Unlock the full potential of your processing equipment with our precision parameter optimization services. Whether you're running Expeller Presses, Roller Mills, Pellet Mills, or Hammer Mills, our engineering team fine-tunes every detail to deliver peak performance.

What We Deliver:

- Customized Machine Settings We analyze and adjust operating speeds, feed rates, and configurations tailored to your specific materials and goals.

- Accessory Selection & Integration Our experts recommend and install the right accessories to enhance throughput and efficiency.

- Performance Tuning We optimize for key metrics like capacity, residual oil content, and particle size — ensuring consistent, high-quality output.

- Data-Driven Adjustments Every recommendation is backed by technical analysis and real-world results.

4) PLANT EXPANSION & FIELD SERVICES

Smarter Growth. Faster Results.

Whether you're scaling operations or fine-tuning performance, our plant expansion and in-field services are built to deliver efficiency, savings, and long-term success. By combining new and rebuilt equipment, we help you reduce costs, accelerate timelines, and maximize ROI.

What We Offer:

- Strategic Equipment Integration We blend new and rebuilt machinery to lower project expenses and speed up delivery — without compromising quality.

- Rapid Installation & Start-Up Our extensive inventory allows for quick deployment, minimizing downtime and getting you back to production faster.

- Onsite Plant Surveys & Evaluations Our team conducts thorough assessments to identify opportunities for improved performance, energy savings, and regulatory compliance.

- Capacity & Efficiency Upgrades We help you expand output, streamline workflows, and optimize resource usage — all tailored to your plant’s specific needs.

- Regulatory & Safety Compliance Our evaluations ensure your facility meets industry standards and environmental guidelines.

5) ONSITE PAINT SERVICES

Fresh Coat. Pro Finish. Industrial-Grade Results.

We’re proud to introduce our new industrial paint booth — now open and ready to serve! Whether you're restoring worn equipment, customizing components, or giving your machinery a fresh new look, our on-site paint services deliver precision, durability, and a flawless finish.

What We Offer:

- Facility-Based Convenience – Drop off your equipment at our industrial paint booth for fast, professional service

- Flexible Scheduling We adapt to your timeline to minimize disruption.

- Competitive Pricing: Premium results without the premium price tag.

- Fast Turnaround Efficient scheduling and streamlined processes mean less downtime for your operation.

- Experienced Technicians Our skilled team brings years of hands-on expertise to every job.

- Precision Application Smooth, even coverage using advanced equipment and expert techniques.

- Versatile Service Range Ideal for machinery, vehicles, parts, and more — large or small.